Understanding Radiation Shielding Design: What It Is, Why It Matters, and How to Get It Right

When building or renovating a facility that uses X-ray or radiation-emitting equipment, adding new equipment, or even changing the number of procedures done, safety considerations start with a radiation shielding design. This important step protects patients, staff, and the public from unnecessary radiation exposure and ensures compliance with state and federal regulations.

In this article, we’ll walk you through what a radiation shielding design is, when and why you need one, and what factors influence an effective design.

What Is a Radiation Shielding Design?

A radiation shielding design—also known as a plan review—is a blueprint created to evaluate how radiation behaves within a room and how best to contain it. It involves detailed calculations to determine the amount and type of protective materials needed (like lead, gypsum, or concrete) to keep radiation exposure within safe limits.

Whether you're installing a CT scanner in a hospital, dental X-ray equipment in a clinic, or imaging systems in a veterinary practice, a shielding design ensures you're building to protect people in adjacent areas.

Why Is Radiation Shielding Design Important?

The primary goal of shielding design is safety. But it's also a regulatory requirement in most U.S. states. Even in states where it’s not explicitly mandated, facilities are still required to demonstrate compliance with radiation dose limits, and a shielding design is the most reliable way to do that.

Key benefits include:

- Protecting staff and the public from unnecessary exposure

- Meeting regulatory requirements set by state agencies

- Ensuring accreditation from organizations like The Joint Commission or ACR

- Minimizing liability and ensuring safe construction planning

When Do You Need a Shielding Design?

You should obtain a radiation shielding design before:

- Installing new X-ray or radiation-emitting equipment

- Renovating or constructing rooms where radiation will be used

- Replacing old equipment (even with the same type, as radiation output may vary)

- Changing the usage or occupancy of adjacent rooms

Failing to conduct a shielding review early can lead to construction delays, budget surprises, or compliance issues during inspections.

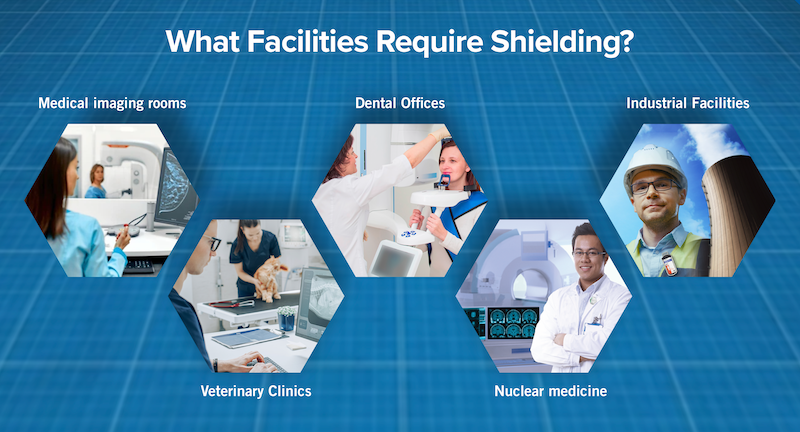

What Equipment and Facilities Require Shielding?

Radiation shielding design is necessary for a wide range of environments and devices, including:

- Medical imaging rooms (CT, fluoroscopy, X-ray, mammography)

- Dental offices (panoramic, intraoral, cone beam CT)

- Veterinary clinics (general imaging, large animal radiography)

- Nuclear medicine and PET departments

- Industrial facilities using X-rays for quality control or inspection

If your facility uses radiation, it likely needs a shielding design.

What Affects the Shielding Requirements?

Effective shielding isn’t one-size-fits-all. It depends on four key factors:

- Radiation Energy – Higher energy sources (like CT scanners) require more shielding than lower-energy devices (like dental X-rays).

- Distance – Radiation exposure decreases with distance. Larger rooms may require less shielding.

- Workload – The number of patients or exposures per week influences total dose output.

- Occupancy – Adjacent areas used by staff or the public must be evaluated to determine appropriate dose limits.

Shielding must comply with standards from the National Council on Radiation Protection and Measurements (NCRP), especially reports 145 (dental), 147 (medical), and 148 (veterinary).

What Materials Are Used for Radiation Shielding?

The most commonly recommended materials in a radiation shielding design include:

- Lead – Dense and highly effective for diagnostic radiation

- Concrete – Often used in floors, ceilings, or exterior walls

- Steel – Used in doors where moderate protection is needed

- Gypsum (Sheetrock) – Provides some protection in low-dose areas

- Leaded Glass – Used for operator viewing windows

The right material—and how much of it you need—will be specified in your shielding report.

What Information Is Needed to Create a Shielding Design?

To ensure accuracy, your shielding design provider will request:

- A to-scale drawing of the room layout

- Equipment type and model

- Estimated workload or number of exposures per week

- Room occupancy information, including what’s above, below, and beside the space

Accurate drawings and data help avoid delays and ensure your design complies with state and federal requirements.

Partner with Experts for Radiation Shielding Design

At LANDAUER, our experienced team completes over 2,500 radiation shielding designs every year. We’re familiar with regulations across all 50 states—and we make the process seamless for medical, dental, veterinary, and industrial clients.

From understanding the science to navigating compliance, we’re here to help you every step of the way.

Ready to Get Started?

Contact LANDAUER today to request your radiation shielding design and ensure your facility is safe, compliant, and built right from the start.