TLD vs OSL: Which Dosimeter Technology is Right for You?

If you’re starting a new dosimetry program or making changes to an existing one, you might be comparing various types of dosimeters and wondering what is the difference between TLD and OSL technology.

Dosimeters have undergone many advances since their earliest form in the 30s. Starting as a simple device that only measured a single dose using an electrical charge, to film badges using photographic film, to crystal-based TLDs, dosimeters have advanced to the most current version: aluminum oxide-based OSL dosimeters.

Dosimeters have become one of the most necessary tools worn by professionals working with radiation, as they measure the accumulated dose of ionized radiation a worker receives over time to help keep their dose as low as reasonably achievable.

Let’s compare TLD vs. OSL so you can determine which will meet your needs.

TLD vs. OSL

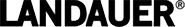

There are several key differences between TLD and OSL dosimeters.

|

Technology |

OSL |

TLD |

|

Component |

Aluminum Oxide (Al2O3:C) | LiF or CaD2 Crystal |

|

Lower Limit of Detection |

Down to 1 mrem | Typically down to 10 mrem |

|

Typical Maximum Wear Period |

Up to 1 year |

3 months |

|

Re-Readable |

Yes | No |

|

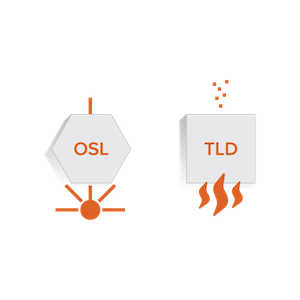

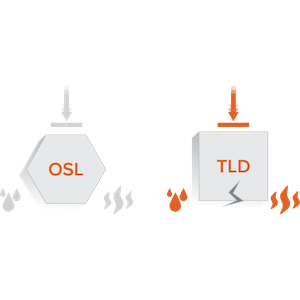

Read Method |

Light (non-destructive) | Heat (destructive) |

|

Motion Detection |

Yes | No |

|

Immediate (Emergency) Readout |

Yes | No |

|

Reporting Details |

Cumulative | Cumulative |

|

Durability |

Rugged; able to withstand drops, temperature extremes, and moisture/humidity | Easily damaged if dropped or exposed to high/low temps or moisture |

Most of the Radiation Safety Officers we work with use these features when deciding what type of dosimeter to choose:

- What is the lowest dose detectable?

- How long should the dosimeter be worn before exchanging it for another?

- Can the dosimeters be re-read?

- How fragile are the dosimeters?

Let’s talk about each of these four main considerations, and how the differences between OSL and TLD features can guide you to the correct choice.

Lowest Radiation Detection Limits

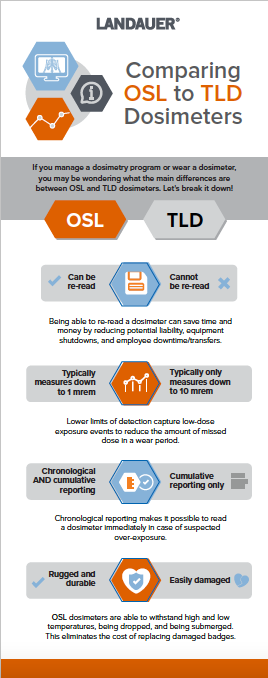

The lower limit of detection (LLD) is usually the first consideration when choosing a dosimeter. This is because having a lower LLD can reduce the amount of missed dose in a wear period, and measuring the full amount of exposure is critical to meeting ALARA protocols.

For example: If an x-ray tech is wearing a badge that has an LLD of 10 mrem, and each month they are exposed to 9mrem, then the reported dose is “minimal”. If this happens for 12 months, the missed dose could be in the order of 100 mrem (9 mrem *12 months=108 mrem).

Over time, this can add up to levels that could potentially exceed ALARA limits. Even if your equipment normally emits higher doses than the LLD, it would be impossible to know if there were smaller doses being received due to faulty shielding or incorrect positioning of the technicians during the procedure.

Note: A word of caution when looking at TLD dosimeters advertised with an LLD under 10 mrem. Under routine conditions, the precision of TLD dosimeters declines sharply for levels of exposure below 10 mrem.

Having an accurate record of complete dose can provide peace of mind to your staff, as well as head off any potential liability issues.

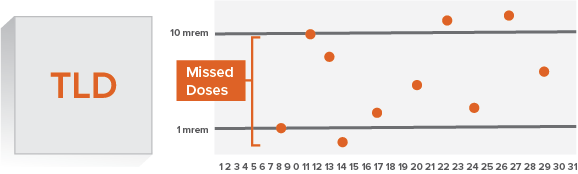

Wear Period

Another consideration when choosing a dosimeter is the wear period. This refers to the time interval the dosimeter is worn by the participant for occupational dose determination. Multiple factors go into the determination of the wear period, including LLD, fade, and risk of getting a higher occupational dose.

Typically, it is recommended that TLD dosimeters are worn for no more than three months. Some are capable of being worn for up to six months, but you will want to verify with the manufacturer prior to purchasing.

OSL dosimeters, on the other hand, can be worn for up to one year before needed to be replaced. This is because the rate of fade is much slower. Having a longer wear period can save time and money, since they have to be replaced less frequently.

Re-Readable Dosimeters

There are several reasons why having the ability to re-read a dosimeter is an indispensable feature of OSL dosimeters. If questions arise regarding exposure, the ability to confirm the initial readout can have multiple benefits:

- Can protect an organization from liability

- Can prevent unnecessary equipment shutdown and testing

- Can prevent unnecessary employee downtime or transfers

Since reading a TLD dosimeter releases the trapped energy, which essentially sets the crystal back to zero, most cannot be re-read.

Since reading a TLD dosimeter releases the trapped energy, which essentially sets the crystal back to zero, most cannot be re-read.

LANDAUER stores all dosimeters for a period of 6 months, so a reread is possible anytime during this interval.

Durability

The fourth concern our customers have when trying to decide between OSL and TLD is the ruggedness of the dosimeter. Generally speaking, the crystals in a TLD dosimeter are more prone to being damaged by high or low temperatures, sudden changes in temperature, moisture, and humidity.

OSL badges are much more rugged. Dropping doesn’t usually cause any damage, and as long as the plastic case remains intact, they can withstand high humidity, being exposed to extreme heat and cold and sudden temperature changes, and being submerged for long periods of time (this means they can handle being put through the washer and dryer!).

If you’re using a less durable dosimeter and it becomes damaged, it needs to be replaced. The costs of these replacements do add up over time. In addition, sometimes the employee is unaware of the damage (or reluctant to admit to it). Wearing a damaged dosimeter may mean their doses are not being recorded accurately.

A Few Other Considerations

Every organization has unique needs, so I want to touch on a few other differentiators to consider: emergency readouts and motion detection.

OSL dosimeters can be read immediately upon suspecting an overdose. Due to the ability to detect motion, it is possible to determine if the exposure occurred while it was being worn. TLD dosimeters, on the other hand, only report on the cumulative dose, and cannot help you determine if there was a high dose incident, or if the exposure happened gradually over the wear period.

The motion detection capabilities of OSL badges also lets us differentiate between exposure that occurred while the dosimeter was being worn, or if it occurred while sitting stationary on a table. This allows us to provide a more accurate picture of exposure levels. If someone accidentally leaves their badge in the x-ray room over the weekend, that exposure can be subtracted from their totals.

Deciding Between OSL and TLD Badges

Despite the technological differences between OSL and TLD badges, making the decision about which dosimeters to use often boils down to two considerations: cost and support.

Generally speaking, TLD badges are usually less expensive, but of course that will vary from company to company based on what is included with the subscription service. When evaluating cost, you should not only consider the monthly/annual fees, but also the cost savings that may come into play when you factor in…

- replacing damaged badges

- equipment and employee downtime

- the potential liability of missed doses

- not having access to medical physicists in case of anomalies

LANDAUER subscription services include access to our in-house team of physicists who will provide support should any anomalies or questions arise. We also provide an easy-to-use self-service portal, where clients can easily add/delete/change participants, download reports, and perform a variety of administrative functions without having to pick up the phone.

When choosing the right dosimeters for your organization, it’s critical to consider every aspect of the purchase. If you still aren’t sure, our helpful team of experts is more than happy to answer your questions so you can make a decision that best fits your needs. Click here to get a quote!